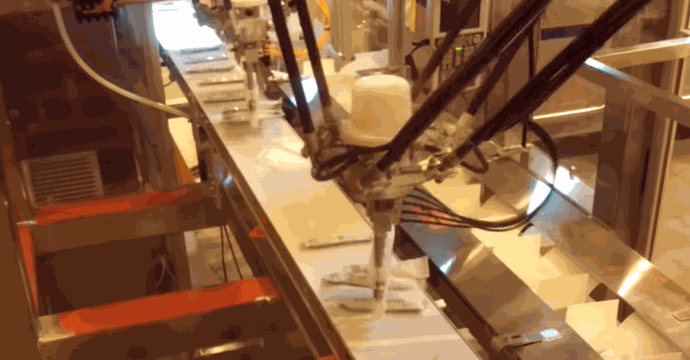

Soft Metal Material Handling

The Gantry in the Video was designed to handle small green parts from a press and then have them placed in trays for a secondary operation.

Because of the secondary operation, the trays became distorted over time so vision was added to calculate the parts spacing and to follow the contour of the tray so maximum fill could be achieved.

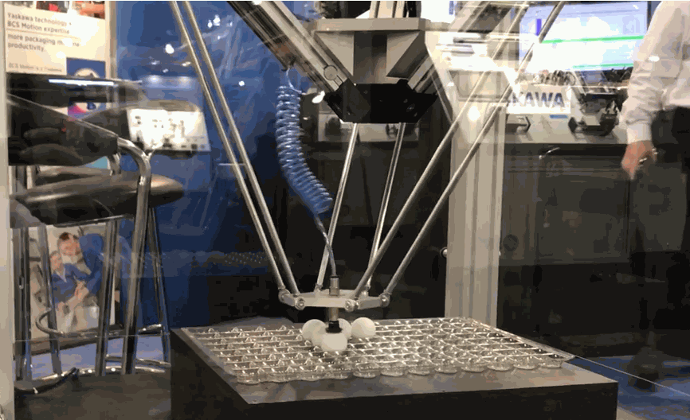

US Navy Wave Simulation Platform

Dual large ball screw linear actuators, 65,000 lbs and 25,000 lbs of force. Large Yaskawa motors 30kw and 22kw provide the power. The climate controlled electrical enclosure is located outside under the machine platform. Motion simulated wave action for shipboard instrumentation testing.